When it comes to fire safety, every second counts—and so does every component. While fire pumps are recognized as the heart of a fire suppression system, one critical part often gets overlooked: the fire pump packing. This compact but powerful sealing system plays a vital role in keeping pumps operating efficiently under pressure, heat, and emergency conditions.

At RainsFlo, we understand the unique challenges fire protection professionals face when it comes to maintaining reliable pumping systems. That’s why we engineer sealing products specifically for fire suppression applications—products that prioritize safety, performance, and longevity.

What Is It and Why Does It Matter?

Fire pump packing refers to the material used to seal the rotating shaft of a fire pump, preventing water leakage while allowing the shaft to spin freely. Without proper packing, water could escape the pump casing, reducing pressure, damaging components, and ultimately compromising the effectiveness of your fire suppression system.

RainsFlo designs fire pump packing to meet the demanding needs of high-speed, high-temperature environments. Made from durable, heat-resistant materials, our packing products help maintain seal integrity under extreme stress—ensuring water pressure is delivered where and when it’s needed most.

Preventive Maintenance Tips for Fire Pump Packing

Even top-tier packing requires regular care. Preventive maintenance can dramatically extend the lifespan and reduce the risk of system failure. Here are a few essential practices to keep in mind:

- Watch for Leaks: Drips or moisture near the shaft are early warning signs of packing wear or improper installation.

- Check Water Pressure: Inconsistent water flow may point to degraded packing or incorrect compression settings.

- Listen for Vibration or Noise: These can signal friction issues, misalignment, or failing materials.

- Inspect Shaft Sleeves: Grooves or pitting may indicate that packing has worn down and is now damaging the shaft.

- Follow Replacement Guidelines: Sticking to manufacturer recommendations ensures consistent protection and performance.

A solid inspection routine can save time, money, and—most importantly—ensure your fire suppression system is always ready to respond. Most importantly, it ensures your fire suppression system is ready when it matters most.

Choosing the Right Fire Pump Packing for Your Needs

Not all packing is created equal. The wrong choice could lead to frequent breakdowns, water loss, or even catastrophic equipment failure. RainsFlo’s fire pump sealing systems are built to solve these issues with precision and durability.

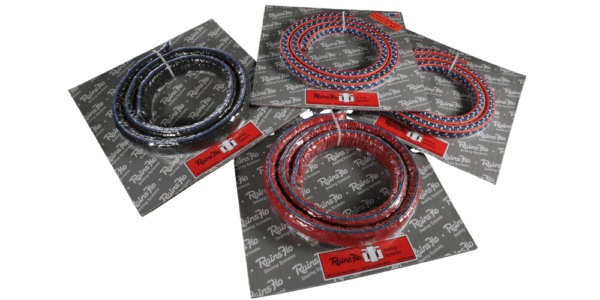

For fire suppression environments, we recommend our Packing Sets for their proven ability to handle extreme pressure and temperature. These sets are engineered with premium materials and designed to fit most standard pump housings.

To streamline your maintenance workflow, tools like the Packing Hooks make removing old packing quicker and safer—especially in high-demand environments where downtime matters.

Why RainsFlo Fire Pump Packing Is Trusted

When lives and property are on the line, shortcuts aren’t an option. RainsFlo’s sealing systems are engineered with the needs of fire safety professionals in mind.

We offer:

- Heat and Pressure Resistance: Reliable performance during emergency conditions

- Minimal Maintenance Requirements: Fewer service calls and lower total cost of ownership

- Simple Installation: Designed for ease-of-use and accurate placement

- Application-Specific Solutions: Engineered to fit a wide range of fire pump types and system designs

Every product is made to deliver consistent sealing performance, even in the harshest environments. That’s why fire safety professionals across industries trust RainsFlo as their sealing partner.

Built to Protect—Every Time

The importance of fire pump packing can’t be overstated. It’s not just about preventing leaks; it’s about ensuring your fire suppression system performs reliably in the moments that matter most. Choosing high-quality, low-maintenance packing from RainsFlo means peace of mind, better protection, and a smarter long-term investment in safety.

RainsFlo

RainsFlo